Reduced consumption: Up to 70% LESS THAN THE COMPETITION

Thrill International glass chillers consume only 5g per second of CO2 with a minimum saving of 50% providing significant cost savings over time.

Low CO2 consumption will reduce the maintenance costs of the glass chiller, increasing the autonomy of the tank and reducing CO2 emissions - they emit the same amount of pollution as human breath.

-56°C in 10 seconds only

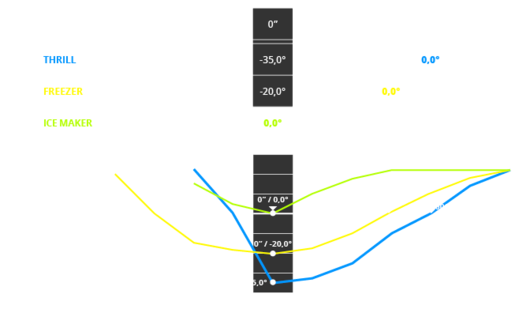

This graphic compares the most common glass cooling methods and measures their effects from 30 minutes before use up to 30 minutes after use.

We compared the three most used methods to cool glasses – Thrill International machines, freezers and ice-machines. As you can see, in just 10 seconds the Thrill International machines lower the glass temperature from 21° C to -35° C. Putting the glass in the freezer lower the glass temperature from 20° C to - 20° C in 30 minutes. Cooling the glass with ice lowers the glass temperature from 20° C to 0° C in ten seconds.

In short, Thrill International glass chillers quickly chill the glass to a lower temperature than other methods, keeping the glass temperature below 0° C for a good 10 minutes.

Electronics suitable for every weather condition

Thrill International products have an electronic system suitable for every weather condition. Electrical parts are sealed and made to resist all weather conditions: humidity, salt, sand, ice, snow and high temperatures.

You can use our machines outdoors in any weather condition.

Silent

Thrill International glass chillers are silent. There is no motor, air compressor or moving parts that can make noise.

The cooling system is based on a spray of CO2 that produces a soft whistle.

It is a delicate, pleasant sound that is not annoying and makes our machines also suitable for peaceful environments.

Surprise your customers

Thrill International glass chillers are eye-catching thanks to their wide LCD screen where you can display videos and pictures.

The condensing smoke that emerges during the chilling process combined with the soft whistle the machine makes, completes the unique experience of a Thrill International machine.

100% stainless steel

Thrill International machines are made from 100% stainless steel, a long-lasting material suitable for professional use.

Thanks to the durability of stainless steel we are able to design our glass chillers with pieces that can be easily removed and washed in the dishwasher.

Vortex WOOD also has a supporting structure made entirely of stainless steel.

2-years warranty and manufacturer reconditioning service

Thrill International products have a 2-year warranty covering manufacturing defects and ensuring safety and reliability: two key features for professional machines.

A complete Manufacturer's Reconditioning and Maintenance Service is available to persevere the integrity and uniqueness of each unit. Thrill has been designed to last a lifetime if carefully used and properly maintained.

![[Translate to English:] Specifiche tecniche gela bicchieri Thrill International [Translate to English:] Specifiche tecniche gela bicchieri Thrill International](/fileadmin/_processed_/c/a/csm_specifiche-tecniche-thrill-international_9e802657ed.png)